MOTORS

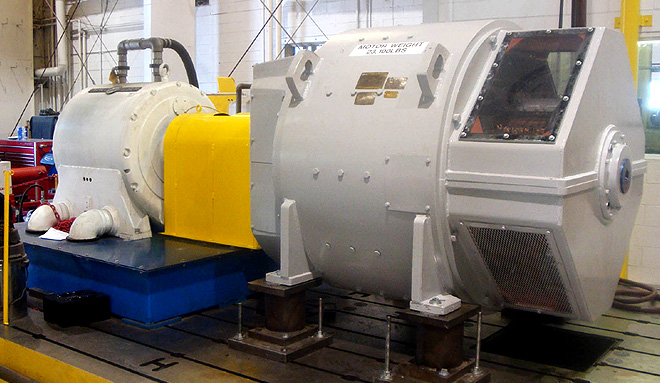

For over 60 years EMC has been re-manufacturing Electric Motors from our centrally located Campus in Chesapeake, VA. Our location allows us to easily serve the maritme, water/waste water, power and industrial markets.

About EMC Motors

- EMC can rewind motors up through 13,200VAC, using epoxy vacuum pressure impregnation (VPI) on all form wound motors through 7KV and B-stage hot pressed coils above 7KV

- An in-house machine shop capable of handling the majority of your machining needs, such as shaft repair/replacement, bearing housing repairs, complete internal horizontal and vertical alignment, etc.

- Dynamic balancing of rotating components, typically to ISO 1940 standards G2.5 and 1.0

- Replacement of stator laminations with low loss, laser cut laminations.

- Shaft repair & replacement, repair of squirrel cage rotors, including rotor bar replacement, lamination replacement and in some cases, complete new rotor manufacturing.

- Upgrading of existing motors, such as rewinding for increased hp or changing bearing design/configuration for optimum vibration and reliability.

- Full voltage no load testing of all motors up through 18,000 hp @ 13.2KV.

- Our Dynamometer capabilities are being increased to offer full load testing, both horizontal and vertical, up to 2500hp (at 1800 rpm)

- Reverse Engineering

- Horsepower upgrades