Power Generation

EMC has over 60 years of experience providing electrical and mechanical services to Fossil and Hydro Power Generation customers, with a wide range of needs. Whether it be utility, industrial or government, we can provide in-place generator rewinds and in-shop total rebuilds and upgrades for all of your complex electrical and mechanical equipment. As part of EMC’s growth and progress to provide the best services to our power generation customers, we have a dedicated Pump Repair Facility at our Chesapeake Campus. EMC has Engineering staff; combined with our state of the art facilities and field service capabilities to maintain your equipment needs.

Power Generation Services Comprehensive Capabilities

Electric Motor Services

- Rewinding up through 13,200 Vac. Using epoxy vacuum pressure impregnation (VPI – 12' Diameter Tank) on all form wound motors through 7KV and B-stage hot pressed coils above 7KV

- Comprehensive machining for shaft repair/replacement, bearing housing repairs, complete internal horizontal and vertical alignment

- Dynamic balancing of rotating components, typically to ISO 1940 standards G2.5 and 1.0

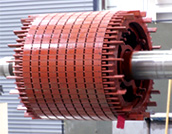

- Replacement of stator laminations with low loss, laser cut laminations

- Rebuilding of squirrel cage rotors, including rotor bar replacement, laminations, replacement and in some cases, complete new rotor manufacturing

- Upgrades of existing motors, such as rewinding for increased HP or changing bearing design/configuration for optimum vibration reliability

- Full voltage no load testing of all motors up through 18,000HP @ 13.2KV

- IEEE 429/NEMA MG-1 Water Submergence test approved on VPI coils

- Dynamometer full load testing up to 2500HP

- Large motor disassembly, reassembly and testing stands

- 50,000 square foot, 3 story high ceiling bay

- 60 ton crane capacity with a 60 foot hook height

- Dynamic balancing to 12.5 tons

- 3.75 MVA power supply with 13.8 KV capability

- Burnout and bake oven

- Vertical and horizontal lathes

- Service Level 1 coatings

Mechanical Services

- Vertical and horizontal pump repair

- Casing repair and re-machining

- Custom design, re-design and machining

- Rotating equipment repair and manufacturing

- New stator and rotor fabrication

- Specialty coating services

- Repair and manufacturing of Babbitt bearings

- Lathes up to 63" x 28" Center to Center

- Vertical Boring Mill up to 7' x 7' x 5' Cube

- Vertical Turret lathe with 10' rotating bed

- Non Destructive testing

Pump Services

- Inspection, Troubleshooting and problem solving

- Turnkey pump removal, transportation, installation, alignment and start-up

- Vibration analysis and laser alignment

- Field Machining

- Complete disassembly, cleaning and inspection

- Comprehensive repairs including remanufacturing OEM parts and components to original or better than original materials specifications

- CMM aided reverse engineering

- Precision dynamic balancing of individual components and rotating assemblies

- Modernization and upgrades including new shafts, bearings, impellers and wear ring materials

- Modernization, repair and upgrades of connected equipment including gearboxes, couplings and motors

- In house media blasting

- Non-destructive testing, including liquid dye penetration, mag particle and ultrasonic

- Engineered coating systems for improved service life and efficiency

- Certified weld program and welders

Switchgear Testing, Repair & Overhaul

- Inspection, Troubleshooting and problem solving

- Turnkey pump removal, transportation, installation, alignment and start-up

- Vibration analysis and laser alignment

- Field Machining

- Complete disassembly, cleaning and inspection

- Comprehensive repairs including remanufacturing OEM parts and components to original or better than original materials specifications

- CMM aided reverse engineering

- Precision dynamic balancing of individual components and rotating assemblies

- Modernization and upgrades including new shafts, bearings, impellers and wear ring materials

- Molded case circuit breakers

- Switchgear and circuit breakers (air & vacuum) up to 15 KV

- Protective relay and instrument testing

- Replacement breakers and pans (new and obsolete)

- Turnkey projects – Switchgear/Transformers

- Start-up services and training

Field Services – Electrical

- Contracting: Master Electrician

- Engineering: Process design, electrical design, estimating and field management

- Preventive and predictive maintenance

- Motor testing

- Infrared thermography

- Troubleshooting: Motors, Generators, Controls, etc.

- Authorized Service Center for Toshiba variable speed drives

Field Services – Mechanical

- Vibration analysis: Monitoring trending and analysis

- Laser alignment

- In-place dynamic balancing

- Mechanical troubleshooting: Pumps, gearboxes, turbines, shafts and spindles

- On-site equipment repairs, removals and reinstallation

Relay Testing

- Testing and calibration of electromechanical and electronic protective relays

- Design and install retrofits of older protection schemes to new microprocessor based protection relays

Full Substation Testing, Service & Repair

- Power circuit breakers, SF6 gas, Vacuum and oil breakers to 230 KV

- Voltage regulators, tap changers

- Control systems (functional testing)

- Acceptance testing, start-up

- Ground grid testing

- KWH meter testing

Storage Capabilities

- Climate-controlled storage facility

- Monthly preventative maintenance performed on stored customer equipment

News/Projects/Technical

- EMC safety milestones.

- EMC is going digital!

- EMC maintenance moves online!

- EMC receives radioactive license amendment 7

- EMC awarded HRSD Gold Award!

- Here we grow again!

- EMC has recently expanded its' Engineering capabilities.

- EMC presented award for SKF Certified Rebuilder.

- Baker DX-12 (Motor winding and surge tester)

- EMC acquires XRF Equipment (Thermo Niton XL2 Gold).

- EMC acquires PDMA MCE (Motor Circuit Evaluator).