NUCLEAR POWER

EMC offers a complete range of in-house, contaminated motor repair services, including the capability to perform full scope refurbishment and rewind of Reactor Coolant Pump motors and Reactor Recirculation Pump motors. EMC provides a state-of-the-art repair facility, decontamination capabilities, engineering, experienced refurbishment staff and expertise for handling contaminated components.

EMC maintains a fleet of specialized containers for transporting radioactive RCP's and Recirculation Motors.

EMC Nuclear Services Building Comprehensive Capabilities

Nuclear Services Building

- 300' Long x 75' Wide x 75' Tall

- 22,500 Square Feet

- 55' Lift Height Under Hook

- 60 ton Lifting Capacity

- Level A Environmentally Controlled

- Maintained at a Negative Pressure

- Stainless Steel 13' by 16' Contaminated Burnout / Bake Out Oven

- Abrasive Blast Booth for Decontamination and SL1 Preparation

- Dedicated Area for Contaminated Steam Cleaning

- 25,000 Lb Dynamic Balance Machine

EMC Nuclear Service Building Staff / Experience

- Reactor Coolant Pump / Reactor Recirculation Motor Full Time Dedicated Staff of Lead Motor Technicians – 25+ years of motor repair, 1st class motor winders – 10+ years of experience and other craft personnel including Machinists, Mechanics, Helpers and HP Technicians

- Forty Chesapeake technicians are Radiation Worker Trained

- 10 RRPM's and 21 RCP's reconditioned/rewound to date

- Staff trained and procedures developed for Westinghouse and GE Reactor Recirculation / Reactor Coolant Pump Motors

- Custom built shipping containers

Motor Testing Capabilities

- Test Stand with 36'x16' T-Slot Base

- 3.75 MVA panel 13.8KV

- Ability to Set-Up Two Motors on Test Stand

- Bearing Cooling Water

- Multi-channel Vibration Analysis

- Multi-Channel Process

- Data Acquisition using Automated Diagnostics for Rotating Equipment (ANDRE)

- Thermal Imaging

- Test Stand has one million pound reinforced concrete mass isolated from the frame – This ensures a very low structural natural frequency for testing

- Capability of virtual witness of motor test run from customer's home or office

- Water Immersion Testing

- Partial Discharge Testing

- Power Factor Tip Up Testing

- Surge, Hi-Pot, Polarization Index, and Megger Testing

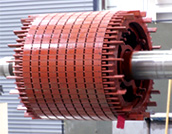

Reactor Recirculation / Reactor Coolant Pump Motor Refurbishment

- Stator Restacking included in Rewind Firm Price - Waste Disposal Included

- Compression Plates and Vent Ducts Replaced

- Replacement Laminations Laser Cut

- Final Core Testing

- Flywheel ASME NDE Testing

- Inspect Oil Coolers, lift system, bearing assemblies, and other auxiliary equipment

- Reverse Engineering – Roamer Arm, Solid Modeling, Finite Element Analysis, Manufacture Drawings

- All Services Performed on EMC campus with EMC technicians, including SL1 Program with EMC Qualified Applicators

- Bearing redesign / upgrade eliminating bearing instability (Oil Whirl) issues seen in many Reactor Recirculation Motors

- Available Westinghouse RCP Modifications (Not Inclusive):

- Truncated Flow Chamber With Existing Viscosity Pump Modification

- Oil Lift System Modification

- Lower Bearing Reservoir Level Indicator Modification (Multi-Port Drain Sump)

- Lower Oil Pot Joint Modification

- Oil Collection System Mounting Modifications

- Flywheel Pawl Modifications

- Flywheel Key Modification

- Anti-Rotation Shock Absorber Mounting Modification

- Dual Element Bearing RTD Modification

News/Projects/Technical

- EMC safety milestones.

- EMC is going digital!

- EMC maintenance moves online!

- EMC receives radioactive license amendment 7

- EMC awarded HRSD Gold Award!

- Here we grow again!

- EMC has recently expanded its' Engineering capabilities.

- EMC presented award for SKF Certified Rebuilder.

- Baker DX-12 (Motor winding and surge tester)

- EMC acquires XRF Equipment (Thermo Niton XL2 Gold).

- EMC acquires PDMA MCE (Motor Circuit Evaluator).